Color sorters, industrial equipment that automatically sorts materials based on visual characteristics such as color and shape, have played a vital role in food processing, agricultural sorting, mining, and recycling industries. Traditional color sorting technology primarily relies on basic image processing algorithms like threshold segmentation and simple morphological processing, often struggling with complex scenarios and subtle differences. With the rapid advancement of artificial intelligence technology, particularly breakthroughs in deep learning within computer vision, the AI sorter industry has experienced revolutionary changes, significantly enhancing sorting accuracy, efficiency, and adaptability.

I. Limitations of Conventional Color Sorters

Traditional color sorters primarily rely on color differences between objects for separation. While effective for materials with distinct color contrasts, they struggle when faced with scenarios requiring differentiation based on shape, texture, or structure despite similar colors (such as walnut shells versus kernels, or stemmed versus stemless raisins). They can "only see color" and fail to comprehend additional characteristics of objects, highlighting the need for next-generation AI sorter solutions.

II. AI+ Color Sorters: Multi-dimensional Recognition, Flexible Selection

Today, next-generation AI sorters integrated with deep learning technology deliver breakthrough upgrades. These advanced AI sorters not only maintain the original high-precision color sorting functionality but also incorporate AI-based intelligent recognition modules. Users can flexibly choose according to actual needs:

Use only traditional color sorting (suitable for simple color-based separation),

Enable only AI mode (for complex shape/texture recognition),

Or activate both modes simultaneously (providing dual protection to improve accuracy).

This means whether sorting decayed or worn hazelnuts, removing plastic fragments and stones from food products, or precisely separating walnut shells from kernels, the AI sorter can "understand" multi-dimensional information without relying on special light sources such as infrared or ultraviolet, greatly enhancing equipment adaptability and stability.

III. Core Advantages of AI Sorter Technology

Deep learning, as a core branch of artificial intelligence, simulates the human brain's working mechanism through multi-layer neural networks, automatically learning feature representations from large amounts of data. In the field of visual recognition, technologies such as Convolutional Neural Networks (CNN), object detection algorithms (YOLO, Faster R-CNN), and semantic segmentation (U-Net, Mask R-CNN) have demonstrated image recognition capabilities surpassing human performance. The modern AI sorter system leverages these technologies to deliver unprecedented performance. Compared to traditional algorithms, deep learning technology offers the following advantages in AI sorters:

High-precision Target Recognition and Classification

In AI sorters, deep learning is primarily used for precise material recognition and classification. By training convolutional neural networks, the system can identify not only color differences but also complex features such as shape, texture, and defect types. For example, in ore sorting, deep learning models can distinguish between ore and gangue, identify fine cracks or impurities; in aquatic product sorting, they can accurately detect foreign objects, diseased areas, or size variations, significantly improving sorting accuracy.

Self-adaptive Capability in Complex Working Conditions

Traditional sorting algorithms are sensitive to lighting changes, dust interference, and mixed materials, while the AI sorter models, trained on extensive samples, possess stronger environmental robustness. Even under uneven lighting, wet material surfaces, or similar-colored objects, the AI sorter maintains stable recognition performance, significantly reducing false rejection rates and missed selection rates. It demonstrates greater robustness against interference factors such as lighting variations, partial occlusion, and posture changes.

Cost-effectiveness: No need for additional expensive special light source systems, lowering the usage threshold.

Operational Flexibility: AI functionality can be turned on or off, compatible with both new and existing processes, protecting users' previous investments.

Comprehensive Recognition: Color + Shape + Texture + Structure, multi-dimensional judgment with lower false rejection rates.

Stability and Reliability: Unaffected by ambient light, maintaining consistent performance under various production conditions.

Integrating deep learning isn't about replacement but empowerment. Next-generation AI sorters enable every food processing plant and agricultural product facility to move toward a new era of high-quality sorting in a smarter, more economical way.

Continuous Evolution Capability: Through incremental learning, the AI sorter model performance is continuously optimized to adapt to new scenarios and materials.

Traditional Color Sorting vs. Deep Learning-Based Ai Sorting

IV. Typical Application Cases

Dimension

Traditional Photoelectric Color Sorter

Deep Learning AI Sorter

Recognition Dimensions

Limited to simple color and brightness comparison

Shape, texture, color tone, internal defects, material properties

Anti-interference Capability

Susceptible to environmental lighting and dust interference

Strong robustness, automatically filters environmental noise

Complex Scenarios

Difficult to distinguish "same color, different material" (homochromatic) objects

Capable of distinguishing high-quality products from defects with extremely similar appearances

Maintenance Cost

Requires frequent manual parameter adjustments (thresholds)

Autonomous model iteration with high environmental adaptability

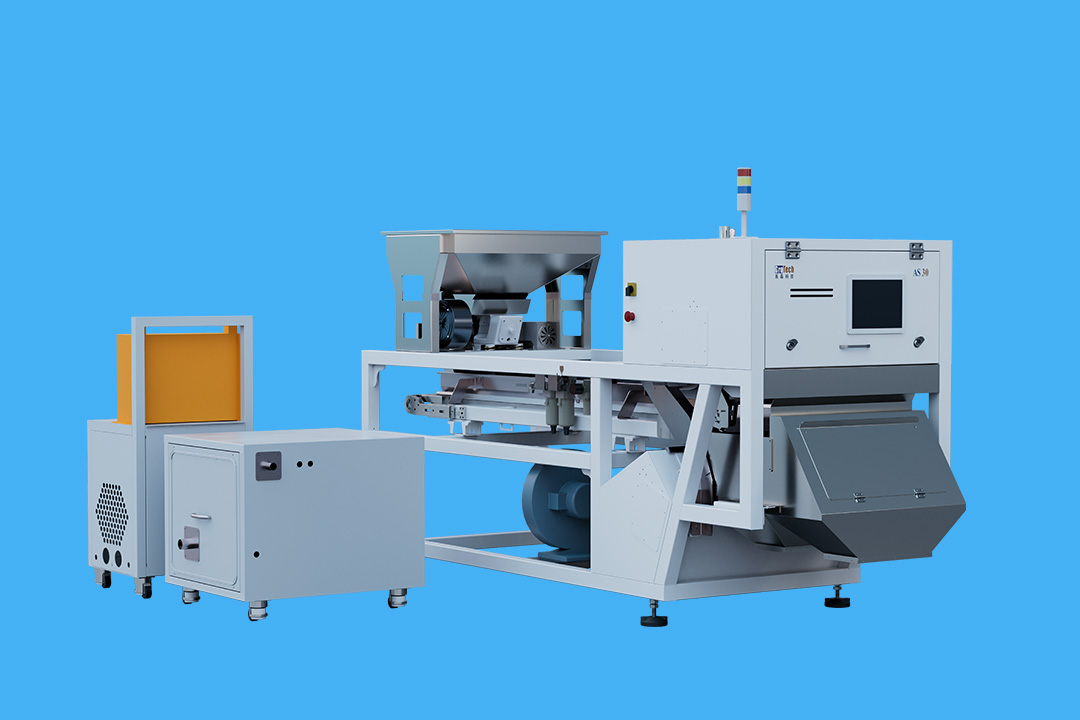

1. Intelligent Nut Sorting System

Hefei Growking Optoelectronic Technology has combined an improved YOLOv5 with Vision Transformer to develop a new generation AI sorter specifically for nuts. This advanced AI sorter is designed for common nuts such as walnuts, almonds, and cashews, and not only identifies surface impurities but also precisely detects quality issues difficult to perceive with the naked eye, including early mold, insect holes, and internal hollow shells. The AI sorter system innovatively integrates multi-spectral imaging technology to identify aflatoxin-contaminated areas, which is crucial for ensuring nut food safety.

In an application at a large nut processing enterprise in Turkey, the AI sorter employed 360° all-around imaging with deep learning analysis, increasing the retention rate of high-quality nuts from 88% with traditional equipment to 99.5%, while raising the detection rate of moldy and insect-damaged nuts to 99.2%. The AI sorter established a nut quality database, continuously learning the characteristic variations of nuts from different origins and seasons, resulting in monthly improvements in sorting precision, truly achieving an "smarter with use" intelligent sorting capability.

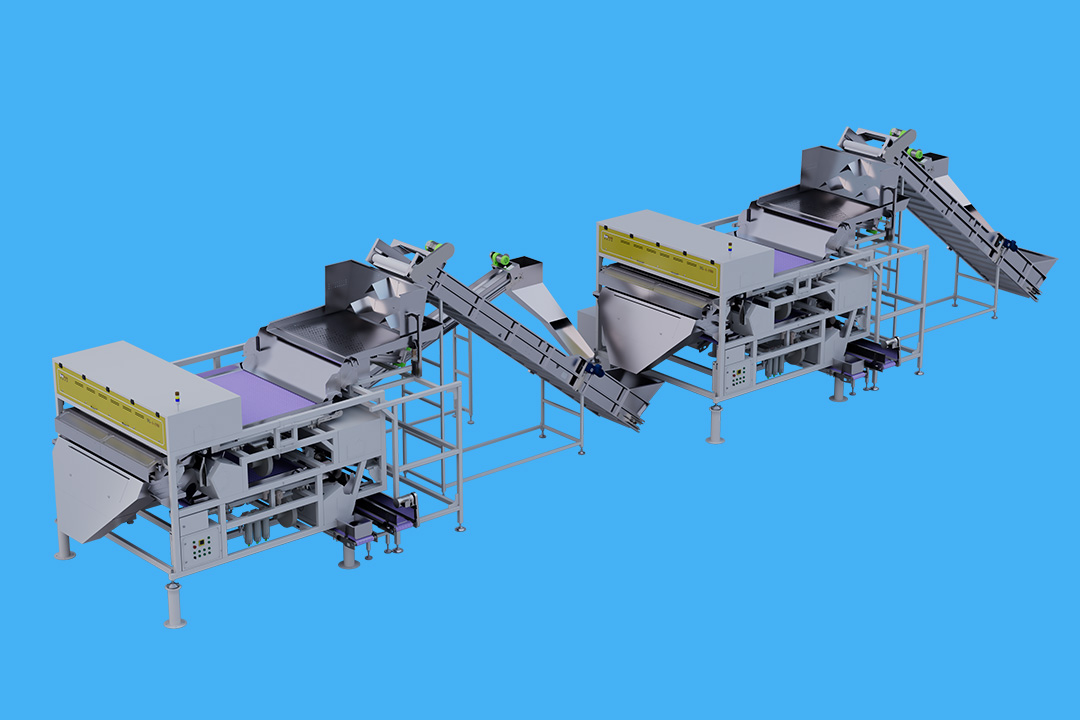

2. Intelligent Ore Sorting Platform

In the mining sector, Hefei Growking Optoelectronic Technology has combined hyperspectral imaging with deep learning to develop an intelligent AI sorter platform suitable for various ores. This AI sorter platform integrates Laser-Induced Breakdown Spectroscopy (LIBS) and high-resolution vision systems, capable of handling sorting requirements for multiple mineral resources including iron ore, silica stone, and pebbles.

For silica stone sorting, the AI sorter employs an improved Mask R-CNN network to precisely identify impurities such as iron and mica in silica stones, particularly addressing the stringent purity requirements of the glass manufacturing industry. The sorted high-purity silica stones are primarily used in glass product manufacturing, especially for wine bottles and high-end glassware that demand exceptional transparency and color quality. Trace iron elements in silica can cause glass to develop a greenish tint, affecting the aesthetics and quality of premium wine bottles. At a photovoltaic material and glass raw material supplier in Sichuan, this AI sorter technology increased the extraction efficiency of 4N grade (99.99%) high-purity silica by 35%, providing downstream glass manufacturers with raw materials meeting international standards, while helping glass product enterprises reduce defective products caused by raw material impurities and enhancing market competitiveness.

For construction-grade pebble sorting, the AI sorter combines 3D point cloud reconstruction technology with multi-angle imaging to solve the problems of irregular pebble shapes and complex textures. Through deep learning models evaluating pebble color uniformity, surface smoothness, and dimensional specifications, the AI sorter successfully achieves automatic grading of decorative-grade, construction-grade, and standard-grade pebbles. In an application case at a building materials enterprise in Jiangsu, the AI sorter increased pebble sorting efficiency by 4 times and improved product premium capability by 25%.

AI sorters are no longer merely sorting tools but have become important nodes connecting the physical world with digital intelligence. In the wave of deep integration between artificial intelligence and traditional industries, these intelligent AI sorters continue to release innovative value across multiple sectors.