1、What is the meaning of powder sorting?

Powder sorting is a type of sorting process that involves separating and removing impurities or defects from powdered materials based on their size, shape, color, or other characteristics. Powder sorting can be used in various industries, such as food processing, pharmaceuticals, cosmetics, and minerals processing.Powder sorting is typically done using specialized equipment, such as air classifiers, sieves, or vibratory screens, which use different principles to sort the powder particles based on their size or density. Advanced technologies such as X-ray and laser diffraction can also be used for more precise sorting applications.Powder sorting is an important process for ensuring the quality, purity, and consistency of powdered materials used in various products. By removing impurities or defective particles, powder sorting can help improve product quality, reduce waste, and increase efficiency.Overall, powder sorting is a critical process in many industries that rely on powdered materials, and there are various techniques and equipment available to help achieve high-quality sorting results.

2. What is powder color sorter?

powder color sorters are specialized machines used for sorting powdered materials based on their color. They use advanced optical sensors and algorithms to detect and remove impurities and defects based on color, allowing for the production of high-quality powders for a variety of applications.

Compared with ordinary color sorters, powder color sorters are more suitable for handling powdery materials with sizes ranging from 100μm to 1000μm (16mesh to 100mesh), such as quartz sand, edible salt, zirconia, etc.

Powder color sorters typically use a combination of cameras and lighting systems to scan and analyze each particle of the powder, and then separate the impurities using mechanical or pneumatic means. Some powder color sorters also use advanced technologies such as X-ray or laser diffraction for more precise sorting.

Powder color sorters are used in various industries such as food processing, pharmaceuticals, cosmetics, and minerals processing, where the quality and purity of the powders are critical to the final product's performance and appearance.

There are many manufacturers of powder color sorters in the market, offering a range of models and features to suit different applications and budgets. When selecting a powder color sorter, it's important to consider factors such as the throughput rate, sorting accuracy, ease of use, maintenance requirements, and customer support services offered by the manufacturer.

3.External features of the powder color sorter

a. Powder objects are very easy to generate dust during the sorting process. It is necessary to design a fully enclosed feeding structure and a dust exhaust system to solve the dust problem.

b. Full blue light irradiation lamp and high-definition sensor can identify materials with a length of more than 1 μm.

c. In order to avoid the damage of the powder to the chute, the powder color sorter is made of strong and wear-resistant tungsten steel. The polished tungsten steel panel chute can effectively avoid material accumulation and increase the output of the color sorter.

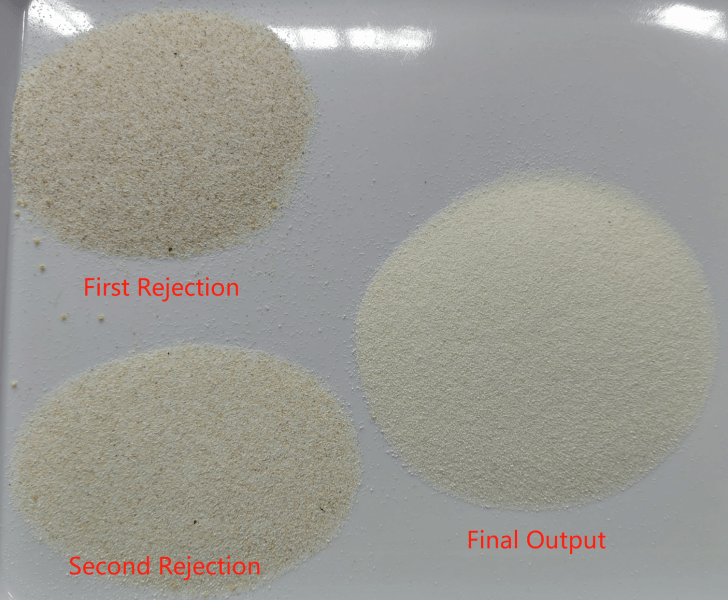

d. Ordinary color sorters only have 63 nozzles per channel, while powder color sorters provide 126 nozzles for each channel. This can significantly improve the rejection accuracy of the color sorter and reduce the take-out ratio.