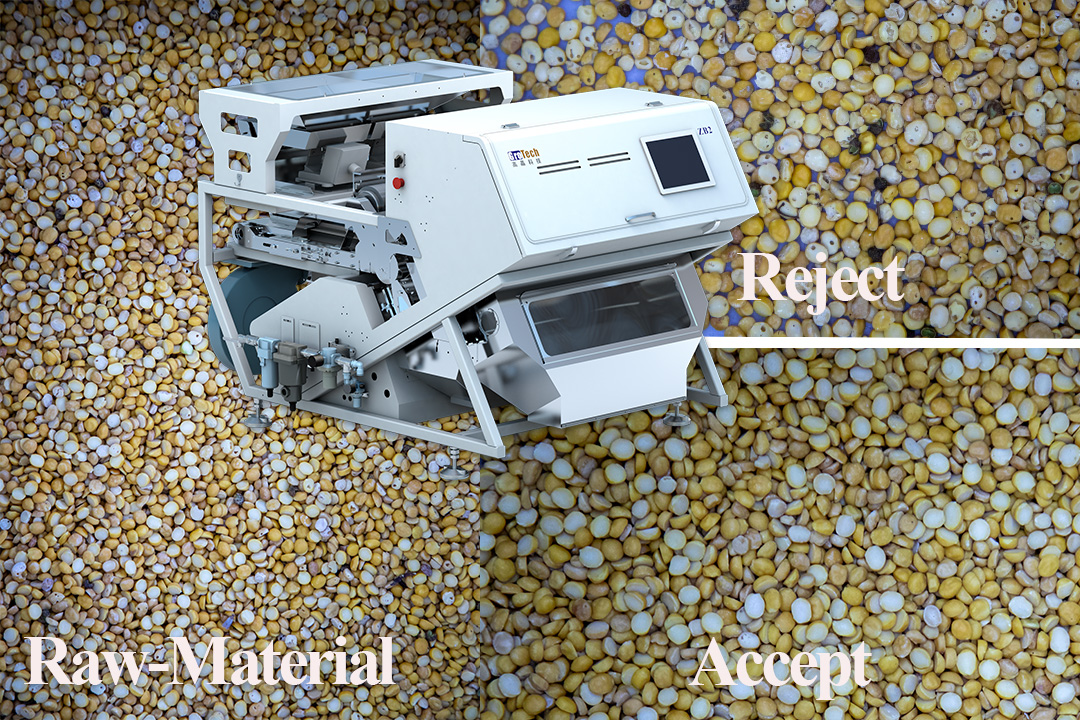

In the processing and sales of beans, insect-damaged beans have always been a “persistent problem” that affects quality and brand reputation. They not only damage the appearance and reduce consumer trust but may also compromise the storage safety of the entire batch. How can producers efficiently remove insect-damaged beans and enhance product quality? The answer is — Ai Bean Color Sorter.

Older generations of color sorters mainly rely on simple color differences to perform sorting.

Minimal color difference: Many insect-damaged beans retain a normal appearance, with only small spots or tiny holes, which conventional machines struggle to detect.

Hidden damage: Some insect damage occurs inside the bean, causing only subtle surface changes that traditional sorters often miss.

Single recognition method: Early machines simulated the human eye with basic optical detection, lacking the ability to judge fine textures, dark spots, or surface defects.

This leads to a common issue: traditional color sorters can remove obviously defective beans, but fail to thoroughly eliminate insect-damaged beans.

With advanced multi-spectral imaging and intelligent algorithms, the new generation of bean color sorters breaks through these limitations:

High-definition detection: Captures subtle dark spots, holes, and color variations on the bean’s surface.

Intelligent learning: Built-in AI continuously learns insect-damage patterns, improving accuracy.

Efficient rejection: High-speed precision air-jet separation removes defective beans instantly.

Better product quality: Sorted beans are fuller, more uniform in color, and meet the demands of premium markets.

Whether soybeans, mung beans, red beans, kidney beans, or cowpeas — the smart color sorter handles them all with ease.

One machine for multiple bean types

Simple, intuitive interface

Saves labor cost and boosts efficiency