Color sorter (optical color sorter, digital color sorter, sorting machine or electronic color sorter) is a device that uses photoelectric detection technology to distinguish the color (or shape, size, texture) of materials according to the difference in their optical properties and automatically divert materials that do not meet the requirements through the spray valve technology. This article tries to give you a preliminary understanding of the color sorter through a simple and easy to understand method.

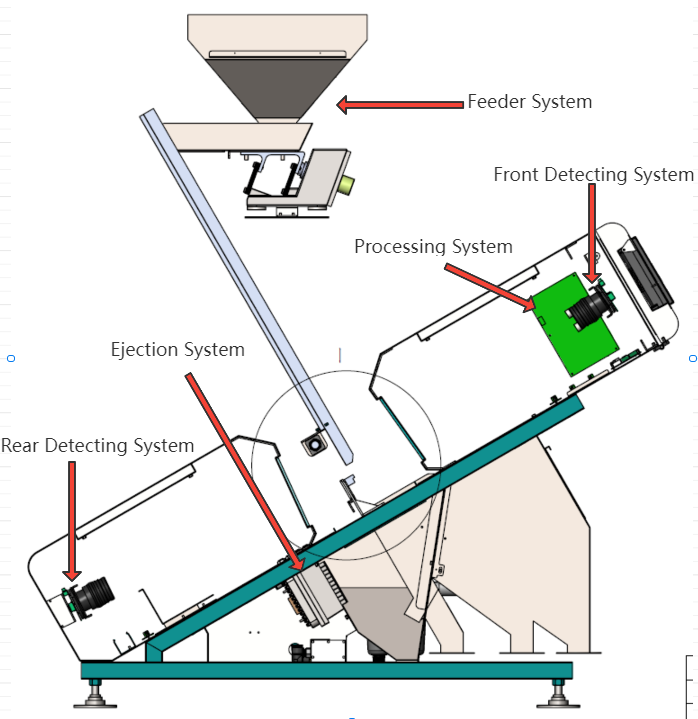

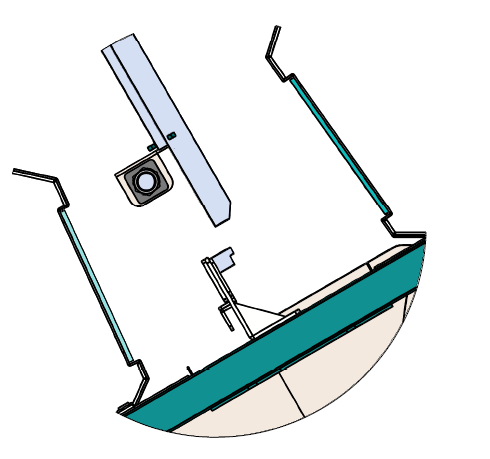

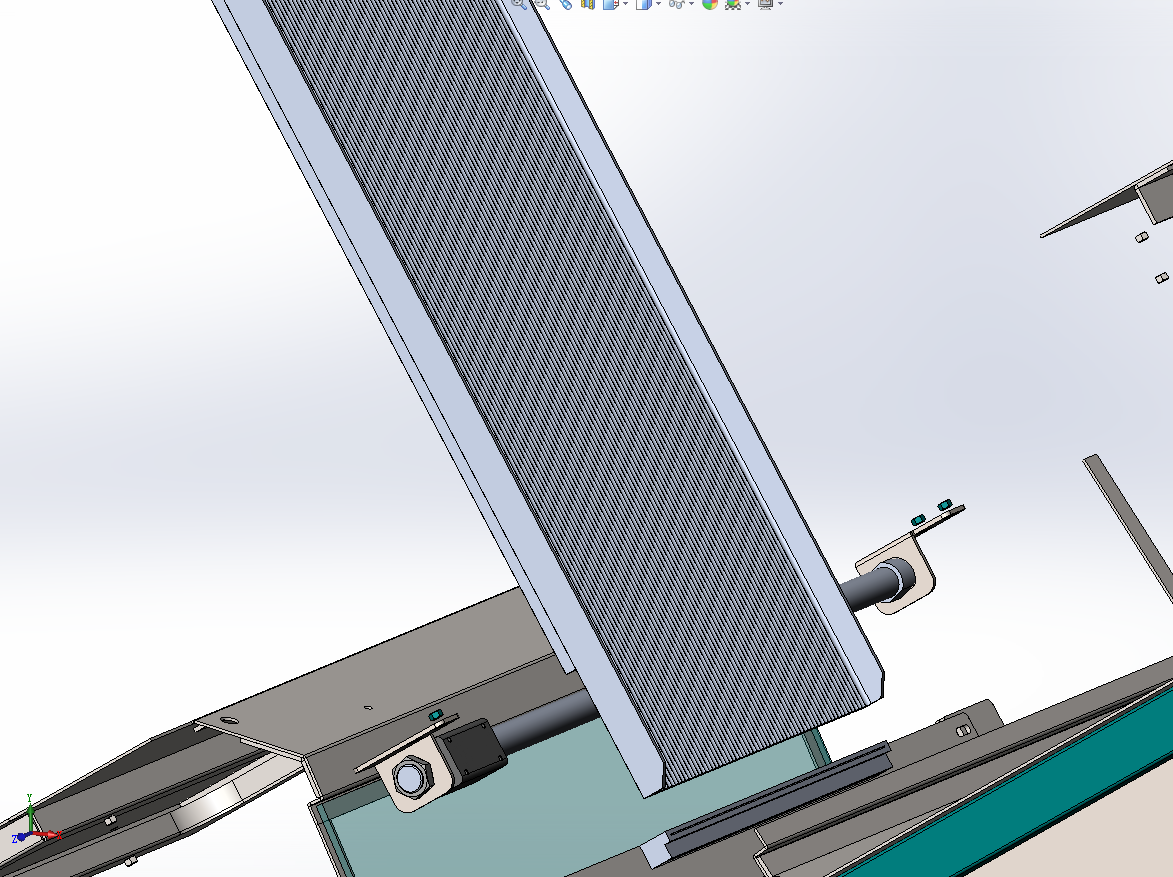

The following diagram shows the current mainstream color sorter model.

From the above diagram, we can see that the color sorter is composed of four main parts.

1, the supply system uses the vibrator to transport the material evenly to the chute, generally each channel has 63/64 chute, the material slides along the chute in the channel to the bottom into the identification area.

2、detecting system detects the material entering the identification area in real time, and generates grayscale or RGB color pictures by shooting the material in high speed movement. Then pictures sent to signal processing and control system.

3、The signal processing module analyzes the received picture data, marks materials which need to be rejected, and the rejection data is sent to the rejection system by the control module.

4、The rejecting system generally adopts air-jet spray valve with 63/64 tiny side-by-side nozzles in one channel. The rejecting system receives the rejecting data from the control module and drives the spray valve to let the designated nozzle open and close, after the nozzle opens, it will spray a high-speed, short, fine beam airflow to the front, and the airflow will blow away the material in front of the nozzle to complete the rejecting action.

Defined from the perspective of optics and electronics, the current development of color sorters has undergone three major upgrades.

The initial generation of color sorter:

The initial generation of color sorter uses photodiode as the acquisition module, microcontroller or CPLD (Complex Programming logic device) as the core processing unit, and fluorescent lamp as the lighting source solution. As the first generation of color sorter, it has obvious defects.

1, CPLD performance and capacity are very low.

2, the limited density of photodiode leads to lower resolution of machine imaging.

3, the light decay of fluorescent lamps is more obvious.

These reasons lead to the lower stability and color sorting performance of the first-generation color sorter.

Second Generation Color Sorter:

Along with the ultra-large-scale integrated circuits, digital signal processing Digital Signal Process and LED lighting and other technological developments. The second generation color sorter uses FPGA or FPGA/DSP hybrid for signal acquisition and processing, and uses LED lighting instead of fluorescent lighting, which greatly improves the stability and performance of the color sorter. The color sorter began to be gradually applied in various industries. But limited by the technology level and cost of sensors, the second generation of color sorter can only capture the grayscale image of the material under the background light irradiation, which is now often referred to as black and white color sorter (Monochromatic color sorter).

Third generation color sorter:

Benefited from the development of CMOS technology, the third generation of color sorter with the help of RGB CCD can identify various color differences of materials. To achieve a variety of heterochromatic algorithm (Bichromatic color), trichromatic algorithm (Trichromatic color) and other complex algorithms. The color sorter manufacturers in various countries started to make efforts to develop models, using more efficient pure FPGA architecture, and excelling in the stability and cost performance of the color sorter. With the shortlisting of Chinese color sorter manufacturers, color sorter has been deeply applied in various industries, representing fields such as rice color sorter, peanut color sorter, soybean color sorter, corn color sorter, sesame color sorter, sunflower seed color sorter, watermelon seed color sorter, coffee bean color sorter, raisin color sorter, cashew color sorter, sea shrimp color sorter, clam color sorter, etc.; industrial industry fertilizer color sorter, plastic particle color sorter, salt color sorter, industrial products color sorting; resource industry iron ore color sorting, quartz sand color sorting, potassium feldspar color sorting; environmental protection industry plastic color sorting, glass color sorting, waste wire color sorting, etc. On the basis of visible light superimposed on X ray, ultraviolet, infrared and other camera technology, can achieve for rice disease spot detection, agricultural mold detection, agricultural crop residue detection, metal detection, plastic material detection, etc.. At the same time, in order to meet market demand, color sorter also began to gradually diversify, from the smallest 18channels (micro sorter), 32channels (mini color sorter) to more than 630channels color sorter came out one after another, single limited by mechanical structure and other reasons, the current mainstream models can be the largest reach 13 channels. Although the third generation of color sorter compared to the second generation has the essence of the improvement, but in part of the sorting and other scenarios still have the heart but not enough. Before the third generation of color sorter is mainly from the color, shape, size three dimensions of detecting, but in most of the shape sorting field, such as raw peanuts need to select the shell cracked or sprouted scenarios, the third generation of color sorter can not be sorted.

Fourth generation of color sorter

The fourth generation color sorter combines deep learning based AI module on the basis of the third generation, using GPU+FPGA architecture. The signals collected by the camera will be handed over to the GPU of the edge computing node to process, because the computing power of GPU greatly exceeds that of FPGA, so it can realize the texture algorithm recognition of materials. The texture algorithm recognition is very important in the material sorting where the material color and shape are not very distinguished, but the texture difference is large.For example, recognizing the gender of crabs, distinguishing the face value of coins, etc. Through the pre-established deep learning model, the color sorter will generate an intelligent sorting algorithm after completing a large amount of learning, and the spray valve processing module receives the processing results from the AI module to reject materials that do not meet the requirements. At present, artificial intelligence technology in the field of color sorter is currently not fully utilized, but from the current achieved effect, artificial intelligence color sorter in some areas of the detecting effect is very good, and the fourth generation of color sorter using the ability of deep learning, theoretically expand the scope of color sorter to an unimaginable degree. This is also the current international first-class color sorter manufacturers are actively developing and promoting models equipped with artificial intelligence. We believe that the fourth generation of color sorter will be an important point in the history of color sorter.

The color sorter composition and implementation is very complex. And the development of color sorter is accompanied by the progress of the times and technology, it is driven by these related industry fields, such as the development of electronic chip FPGA field, the development of optical Optical CCD, the development of mechanical processing technology, the development of color and image recognition field. In this paper, only a brief introduction to the history of the development of color sorting machine, and the subsequent subdivision of the module will be developed to introduce.

Keywords for the next paper.

Application scenarios of color sorter: industrial screening field, agricultural screening field, environmental protection field, ore field

The light source of color sorter: visible light, invisible light, brightness, chromaticity, saturation

Spectrum of color sorter: single spectrum, multi-spectrum, hyperspectrum, polarization camera

Recognition algorithm of color sorter: size algorithm, shape algorithm, grayscale algorithm, heterochromatic algorithm, trichromatic algorithm, artificial intelligence algorithm