Corn contains a large amount of nutritional and health-care substances. The glutathione it contains is an anti-cancer factor. Nutrients such as riboflavin and vitamins have a great effect on the prevention of heart disease, cancer and other diseases. Therefore, corn, as a coarse grain with high nutritional value, is deeply loved by the public. But how do you get good quality corn? Of course, it is inseparable from the corn color sorter.

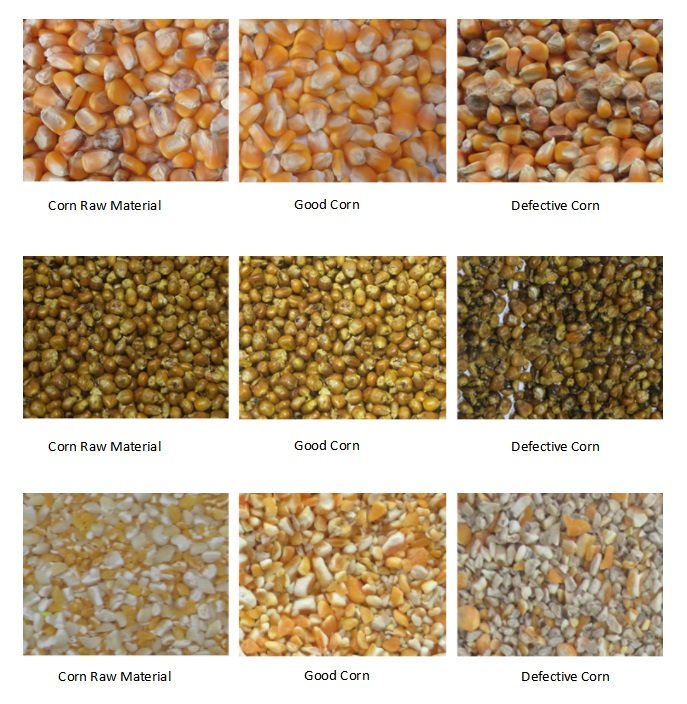

In traditional corn selection, most of them are manually selected. The appearance of corn sorting machine is a great change of the times. The corn color sorter can automatically sort out mildew, disease spots, black spots and redness in corn by using photoelectric detection technology according to the difference of corn optical characteristics.

Compared with manual selection, in addition to saving labor, time, high efficiency and low processing cost, corn color sorter can also improve the quality, economic and social benefits of the selected products. If you want corn to sell at a good price, color selection is essential. Hefei Growking Optoelectronic intelligent color CCD corn color sorter, intelligent sorting, one step in place, professionally removes moldy kernels, imperfect kernels, burnt kernels and other different-colored particles in corn, the corn is good in color and quality, and naturally more market.

Warm tips from corn color sorter manufacturer:

Precautions for installation of corn color sorter

Unpacking and inspection of the color sorter: After receiving the machine, care should be taken when unpacking to avoid unnecessary damage to the parts and check the integrity of the parts and equipment.